Analog to Digital Converter (ADC) driver software usually captures a single block of samples; if a larger dataset (or continuous stream) is required, it can be very difficult to merge multiple blocks without leaving any gaps.

In this post I describe a utility that runs from the command-line, and performs continuous data capture to a Linux First In First Out (FIFO) buffer, that can be accessed by another Pi program, written in any language. The software also captures a microsecond time-stamp for each data block, that can be used to validate the timing, making sure there are no gaps.

To achieve this performance, I’m heavily reliant on Direct Memory Access (DMA) as described in a previous post; if you are a newcomer to the technique, I suggest you experiment with that code first, since it is much simpler.

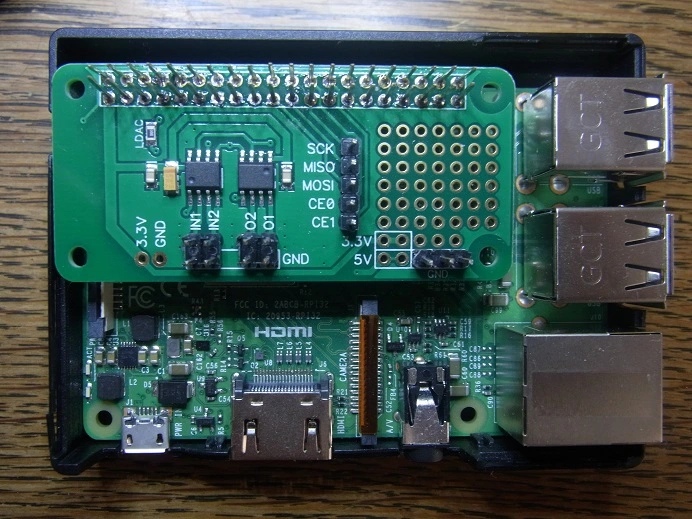

ADC hardware

For this demonstration I’m using the ‘ADC-DAC Pi Zero’ from AB Electronics; despite the name, it is compatible with the full range of RPi boards. It uses an MCP3202 12-bit ADC with 2 analog inputs, measuring 0 to 3.3 volts at up to 60K samples per second. It also has 2 analog outputs from an MCP4822 DAC; I had planned to include these in the current software, but ran out of time – they may well feature in a future post.

As is common with mid-range ADC boards, it uses the Serial Peripheral Interface zero (SPI0) for data transfers. It has a 4-wire interface (plus ground) comprising transmit & receive data, a clock line, and Chip Enable zero (CE0).

ADC serial protocol

To get a sample from the ADC, it is necessary to drive the Chip Enable (CE) line low, clock in a command, clock out the data, and drive CE high. The SPI clock signal isn’t just used for data transmission, it also controls the internal logic of the ADC, so there is a limit on how fast it can be toggled; the data sheet is a bit vague on this subject (only specifying a limit of 1.8 MHz with 5V supply, and 0.9 MHz with 2.7V), so I’ve used a conservative value of 1 MHz. The data format is a 4-bit command, a null bit, and 12-bit response, making an awkward size of 17 bits. My software ignores the least-significant bit, so uses more convenient 16-bit transfers, with a maximum rate of 60K samples/sec. The command and response format is:

COMMAND:

Start bit: 1

Single-ended mode 1

Channel number 0 or 1

M.S. bit first 1

Dummy bits for response 0 0 0 0 0 0 0 0 0 0 0 0

RESPONSE:

Undefined bits (floating) x x x x

Null bit 0

Data bits 11 to 0 x x x x x x x x x x x x

So the command for channel 0 is D0 hex, channel 1 is F0 hex. The following oscilloscope trace shows 2 transfers at 50,000 samples per second; you can see that the CE line goes low one clock cycle before the start of the transaction, and goes high on the last clock edge. This is because I’ve used the automatic-CE capability of the SPI interface, which provides very accurate timings.

The voltage is calculated by taking the value from the lower 11 bits, multiplying by the reference voltage, and dividing by the full-scale value, so 0x2AC * 3.3 / 2048 = 1.102 volts.

Raspberry Pi SPI

The SPI controller has the following 32-bit registers:

- CS (control & status): configuration settings, and status information

- FIFO (first-in-first-out): 16-word buffers for transmit & receive data

- CLK (clock divisor): set the clock rate of the SPI interface

- DLEN (data length): the transmit/receive length in bytes (see below)

- LTOH (LOSSI output hold delay): not used

- DC (DMA configuration): set the trigger levels for DMA data requests

The bit fields within these registers are described in the BCM2835 ARM Peripherals document available here, and the errata here; I’ll be concentrating on aspects that aren’t fully described in that document.

CS bits 0 & 1: select chip enable. The terms Chip Enable (CE) and Chip Select (CS) are used interchangeably to describe the hardware line that enables communication with the ADC or DAC chip, but CS is confusing as there is a CS (Control & Status) register as well, so I prefer to use CE. Bits 0 & 1 of that register control which CE line is used; the ADC is on CE0, and the DAC is on CE1.

CS bits 4 & 5: Tx and Rx FIFO clear. When debugging, it is quite common for there to be data left in the FIFOs, so it is a good idea to clear the FIFOs on startup.

CS bit 7: transfer active. When in DMA mode, set this bit to enable the SPI interface for data transfers. The transfer will start when there is data to be transmitted in the FIFO; after the specified length of data has been transferred, this bit will be cleared.

CS bit 8: DMAEN. This does not enable DMA, it just configures the SPI interface to be more DMA-friendly, as I’ll describe below. It isn’t necessary to use DMA when DMAEN is set; when trying to understand how this mode works, I used simple polled code.

CS bit 11: automatically deassert chip select. When set, the SPI interface can automatically frame each 16-bit transfer with the CE line; setting it low before the start, and high at the end, as shown in the oscilloscope trace above.

There is a confusing interaction between Transfer Active bit (TA), and the Data Length register (DLEN). Basically there are 2 very different ways of setting the data length at the start of a transfer:

- If TA is clear, the length (in bytes) must first be set in the DLEN register. Then TA is set, and the transaction will start when there is data in the transmit FIFO.

- If TA is set, the DLEN register is ignored. The length (in bytes) must first be written into the FIFO, together with some of the CS register settings, then the transfer will start when data is written to the transmit FIFO.

I generally use the first method, but either is workable providing you have a clear idea of the whether the transfer is active or not – don’t forget that it is automatically cleared when the length becomes zero.

An additional complication comes from the fact that DMA transfers and FIFO registers are 4 bytes wide, but we’re only doing 2-byte transfers to the ADC. The remaining 2 bytes aren’t automatically discarded; they stay in the FIFO to be used by the next transaction. It is possible to use this fact, and economise on memory by having 2 transmit words in one 4-byte memory location, but this can get really confusing (particularly with method 2) so I use a clear-FIFO command in each transfer to remove the extra. This means that the transmit & receive data only uses 16 bits in every 32-bit word.

SPI, PWM and DMA initialisation

To initialise the SPI & PWM controllers, we need to know what master clock frequency they are getting, in order to calculate the divisor values that’ll produce the required output frequencies. The frequencies (in MHz) depend on which Pi hardware version we’re using:

Version PWM SPI REG_BASE DMA channels used by OS

ZeroW 250 400 0x20000000 0, 2, 4, 6

Zero2 250 250 0x3F000000 0, 2, 3, 4, 6

1 250 250 0x20000000 0, 2, 4, 6

2 250 250 0x3F000000 0, 2, 4, 6

3 250 250 0x3F000000 0, 2, 4, 6

4 or 400 375 200 0xFE000000 2, 11, 12, 13, 14

The channel usage was determined by running my rpi_disp_dma utility, and the PWM & SPI clock values were checked using the rpi_adc_stream application in test mode, as described later in this post.

Sadly, this table isn’t telling the whole truth with regard to the values for SPI master clock. These are the values in normal operation, however if the CPU temperature is too high, its clock frequency is scaled back, and so is the SPI master clock. Mercifully the PWM frequency remains constant, so the sample rate of our code is unaffected, but as you’ll see from the oscilloscope trace above, if we’re running at 50K samples per second, there isn’t a lot of spare time, so if the SPI clock slows down, the transfers could fail to complete, causing garbage data and/or DMA timeouts.

This will only be a problem if you’re working close to the maximum sample rate, and if necessary, there are various workarounds you can use; for example, increase the SPI frequency, since the ADC does seem to tolerate values greater then 1 MHz, or fix the CPU clock frequency by changing the settings in /boot/config.txt.

The table also includes a list of active DMA channels, obtained by my rpi_disp_dma utility, as described later. Based on this result, I generally use channels 7, 8 & 9 in my code but of course there is no guarantee these will remain unused in any future OS release. If in doubt, run the utility for yourself.

Using DMA

The only way of getting ADC samples at accurately-controlled intervals is to use Direct Memory Access (DMA). Once set up, this acts completely independently of the CPU, transferring data to & from the SPI interface. We probably don’t want to run the ADC flat out, so need a method of triggering it after a specific time delay. In the absence of any hardware timers (surprisingly, the RPi CPU doesn’t have any conventional counter/timers) we’re using the Pulse Width Modulation (PWM) interface for timed triggering (which is generally known as ‘pacing’).

So we need to set up 3 DMA channels; one for transmit data, one for receive data, and one for pacing. I’ve tried to make the process of doing this as simple as possible, with a very clean structure. The DMA Control Blocks (CBs) and data must be in un-cached memory, as described in my previous post, so I’ve simplified the program steps to:

- Prepare the CBs and data in user memory.

- Copy the CBs and data across to uncached memory

- Start the DMA controllers

- Start the DMA pacing

To keep the organisation of the variables very clear, they are in a structure that can be overlaid onto both the user and the uncached memory. Here is the code for steps 1 and 2:

typedef struct {

DMA_CB cbs[NUM_CBS];

uint32_t samp_size, pwm_val, adc_csd, txd[2];

volatile uint32_t usecs[2], states[2], rxd1[MAX_SAMPS], rxd2[MAX_SAMPS];

} ADC_DMA_DATA;

void adc_dma_init(MEM_MAP *mp, int nsamp, int single)

{

ADC_DMA_DATA *dp=mp->virt;

ADC_DMA_DATA dma_data = {

.samp_size = 2, .pwm_val = pwm_range, .txd={0xd0, in_chans>1 ? 0xf0 : 0xd0},

.adc_csd = SPI_TFR_ACT | SPI_AUTO_CS | SPI_DMA_EN | SPI_FIFO_CLR | ADC_CE_NUM,

.usecs = {0, 0}, .states = {0, 0}, .rxd1 = {0}, .rxd2 = {0},

.cbs = {

// Rx input: read data from usec clock and SPI, into 2 ping-pong buffers

{SPI_RX_TI, REG(usec_regs, USEC_TIME), MEM(mp, &dp->usecs[0]), 4, 0, CBS(1), 0}, // 0

{SPI_RX_TI, REG(spi_regs, SPI_FIFO), MEM(mp, dp->rxd1), nsamp*4, 0, CBS(2), 0}, // 1

{SPI_RX_TI, REG(spi_regs, SPI_CS), MEM(mp, &dp->states[0]), 4, 0, CBS(3), 0}, // 2

{SPI_RX_TI, REG(usec_regs, USEC_TIME), MEM(mp, &dp->usecs[1]), 4, 0, CBS(4), 0}, // 3

{SPI_RX_TI, REG(spi_regs, SPI_FIFO), MEM(mp, dp->rxd2), nsamp*4, 0, CBS(5), 0}, // 4

{SPI_RX_TI, REG(spi_regs, SPI_CS), MEM(mp, &dp->states[1]), 4, 0, CBS(0), 0}, // 5

// Tx output: 2 data writes to SPI for chan 0 & 1, or both chan 0

{SPI_TX_TI, MEM(mp, dp->txd), REG(spi_regs, SPI_FIFO), 8, 0, CBS(6), 0}, // 6

// PWM ADC trigger: wait for PWM, set sample length, trigger SPI

{PWM_TI, MEM(mp, &dp->pwm_val), REG(pwm_regs, PWM_FIF1), 4, 0, CBS(8), 0}, // 7

{PWM_TI, MEM(mp, &dp->samp_size), REG(spi_regs, SPI_DLEN), 4, 0, CBS(9), 0}, // 8

{PWM_TI, MEM(mp, &dp->adc_csd), REG(spi_regs, SPI_CS), 4, 0, CBS(7), 0}, // 9

}

};

if (single) // If single-shot, stop after first Rx block

dma_data.cbs[2].next_cb = 0;

memcpy(dp, &dma_data, sizeof(dma_data)); // Copy DMA data into uncached memory

The initialised values are assembled in dma_data, then copied into uncached memory at dp. The control blocks are at the start of the structure, to be sure they’re aligned to the nearest 32-byte boundary. Then there is the data to be transmitted, and some storage for the timestamps, that is marked as ‘volatile’ since it will be modified by DMA.

The format of a control block is:

- Transfer Information (TI): address increment, trigger signal (data request), etc.

- Source address

- Destination address

- Transfer length (in bytes)

- Stride: skip unused values (not used)

- Next Control Block: zero if last block

- Debug: additional diagnostics

Looking at the first control block (CB 0) in detail:

#define SPI_RX_TI (DMA_SRCE_DREQ | (DMA_SPI_RX_DREQ << 16) | DMA_WAIT_RESP | DMA_CB_DEST_INC)

{SPI_RX_TI, REG(usec_regs, USEC_TIME), MEM(mp, &dp->usecs[0]), 4, 0, CBS(1), 0}, // 0

Transfer info: wait for data request from SPI receiver

Source address: microsecond counter register

Destination address: memory

Transfer length: 4 bytes

Stride: not used

Next control block: CB 1

Debug: not used

The source and destination addresses are more complex than usual, since they must be bus address values, created using a macro that takes a pointer to a block of mapped memory, and the offset within that block.

For this application, we need to keep re-transmitting the same bytes to request the data, but reception is in the form of long blocks of data; I’ve specified 2 blocks, that form a ‘ping-pong’ buffer, with the microsecond timestamp being stored at the start of each block, and a completion flag at the end. Ideally, the user code will be emptying one buffer while the other is being filled by DMA, but if the code is too slow, the overrun condition can be detected, and the data discarded.

Starting DMA

When we start the 3 DMA channels, they will all remain idle until the condition specified in TI is fulfilled:

init_pwm(PWM_FREQ, pwm_range, PWM_VALUE); // Initialise PWM, with DMA

*REG32(pwm_regs, PWM_DMAC) = PWM_DMAC_ENAB | PWM_ENAB;

*REG32(spi_regs, SPI_DC) = (8<<24) | (1<<16) | (8<<8) | 1; // Set DMA priorities

*REG32(spi_regs, SPI_CS) = SPI_FIFO_CLR; // Clear SPI FIFOs

start_dma(mp, DMA_CHAN_C, &dp->cbs[6], 0); // Start SPI Tx DMA

start_dma(mp, DMA_CHAN_B, &dp->cbs[0], 0); // Start SPI Rx DMA

start_dma(mp, DMA_CHAN_A, &dp->cbs[7], 0); // Start PWM DMA, for SPI trigger

To set the data-gathering in motion, we just enable PWM.

// Start ADC data acquisition

void adc_stream_start(void)

{

start_pwm();

}

This sends a data request, which is fulfilled by DMA channel A (CB7), and nothing else happens; the SPI interface remains idle. However, on the next PWM timeout, CBS 8 & 9 are executed, which loads a value of 2 into the DLEN register, and sets the SPI transfer active. This triggers a request for Tx data from DMA channel C (CB6); when the first 2 bytes have been transferred, DMA channel B is triggered to store the microsecond timestamp (CB0), and the data (CB1). Since the transfer is no longer active, the DMA channels will all wait for their trigger signals, and the cycle will repeat, except that CB1 is storing the incoming ADC data in a single block.

Once the required number of samples have been received, CB2 sets a flag to indicate the buffer is full, then CB4 starts filling the other buffer.

Compiling and running the code

The C source code for the streaming application rpi_adc_stream and the DMA detection application rpi_disp_dma are on github here. You’ll also need the utility files rpi_dma_util.c and rpi_dma_util.h from the same directory.

Edit the top of rpi_dma_util.h to indicate which hardware version you are using (0 to 4, or 2 for the Zero2). The applications are compiled using a minimal command line:

gcc -Wall -o rpi_disp_dma rpi_disp_dma.c rpi_dma_utils.c

gcc -Wall -o rpi_adc_stream rpi_adc_stream.c rpi_dma_utils.c

You can add extra compiler options such as -O2 for code optimisation, but this isn’t really necessary.

Both of the utilities have to be run using ‘sudo’, as they require root privileges.

DMA channel scan

The DMA scan is run as follows:

Command:

sudo ./rpi_disp_dma

Response (Pi ZeroW):

DMA channels in use: 0 2 4 6

There is only one command line option, ‘-v’ for verbose operation, which prints out all the DMA register values.

By default, DMA_CHAN_A, B and C are defined in rpi_dma_utils.h as channels 7, 8 and 9, so should not conflict with those used by the OS.

ADC streaming

There are various command-line options, but it is suggested that you start by using the -t option to check the SPI and PWM interfaces are running correctly:

Command:

sudo ./rpi_adc_stream -t

Response:

RPi ADC streamer v0.20

VC mem handle 5, phys 0xde50f000, virt 0xb6f5f000

Testing 1.000 MHz SPI frequency: 1.000 MHz

Testing 100 Hz PWM frequency: 100.000 Hz

Closing

A small error in the reading (e.g. 100.010 Hz) doesn’t indicate a fault, it is just due to the limited resolution of the timer that is making the measurement.

The command-line options are case-insensitive:

-F <num> Output format, default 0. Set to 1 to enable microsecond timestamps.

-I <num> Number of input channels, default 1. Set to 2 if both channels required.

-L Lockstep mode. Only output streaming data when the Linux FIFO is empty.

-N <num> Number of samples per block, default 1.

-R <num> Sample rate, in samples per second, default 100.

-S <name> Enable streaming mode, using the given FIFO name.

-T Test mode

-V Verbose mode. Enable hexadecimal data display.

Running the utility with no arguments will perform a single conversion on the first ADC channel (marked ‘IN1’):

Command:

sudo ./rpi_adc_stream

Response:

RPi ADC streamer v0.20

VC mem handle 5, phys 0xde50f000, virt 0xb6fd1000

SPI frequency 1000000 Hz

ADC value 686 = 1.105V

Closing

If the input isn’t connected to anything, you will get a random result; either short-circuit the input pins, or connect them to a known voltage source (less than 3.3V) to get a proper reading.

To stream the voltage values, it is necessary to specify the number of samples per block, the sample rate, and a Linux FIFO name; you can choose (almost) any name you like, but it is recommended to put the FIFO in the /tmp directory, e.g.

Command:

sudo ./rpi_adc_stream -n 10 -r 20 -s /tmp/adc.fifo

Response:

RPi ADC streamer v0.20

VC mem handle 5, phys 0xde50f000, virt 0xb6f7e000

Created FIFO '/tmp/adc.fifo'

Streaming 10 samples per block at 20 S/s

The software is now waiting for another application to open the Linux FIFO, before it will start streaming. The FIFO is very similar to a conventional file, so some of the standard file utilities can be used, e.g. ‘cat’ to print the file. Open a second Linux console, and in it type:

Command:

cat /tmp/adc.fifo

Response (with 1.1V on ADC 'IN1'):

1.102,1.104,1.104,1.102,1.104,1.104,1.110,1.104,1.102,1.102

1.105,1.104,1.104,1.104,1.105,1.102,1.102,1.104,1.104,1.104

..and so on, at 2 blocks per second..

Hit ctrl-C to stop this command, and you’ll see that the streamer can detect that there is nothing reading the FIFO, so reports ‘stopped streaming’, though it does continue to fetch data using DMA, since this has minimal impact on any other applications.

You’ll note that it hasn’t been necessary to run the data display command using ‘sudo’; it works fine from a normal user account. It is important to limit the amount of code that has to run with root privileges, and the Linux FIFO interface is a handy way of achieving this.

There is a ‘-f’ format option, that controls the way the data is output. Currently there is only one possibility ‘-f 1’ which enables a microsecond timestamp on each block of data, e.g.

Command in console 1:

sudo ./rpi_adc_stream -n 1 -r 10 -f 1 -s /tmp/adc.fifo

Response:

Streaming 1 samples per block at 10 S/s

Command in console 2:

cat /tmp/adc.fifo

Response in console 2 (with 1.1 volt input):

0,1.102

100000,1.104

200000,1.102

300001,1.105

400001,1.104

..and so on, at 10 lines per second

The timestamp started at zero, then incremented by 100,000 microseconds every block. It is a 32-bit number, so if you want to measure times longer than 7 minutes, you will need to detect when the value has wrapped around.

If 2 input channels are enabled using ‘-i 2’, then the overall sample rate remains unchanged, each channel has half the samples. In the following example, I’ve also enabled verbose mode, to see the ADC binary data:

Command in console 1:

sudo ./rpi_adc_stream -n 2 -i 2 -r 10 -f 1 -s /tmp/adc.fifo -v

Response in console 1:

Streaming 2 samples per block at 10 S/s

Response when streaming starts:

Started streaming to FIFO '/tmp/adc.fifo'

F2 AD 00 00 F0 01 00 00

F2 AE 00 00 F0 01 00 00

F2 AE 00 00 F0 01 00 00

F2 AE 00 00 F0 00 00 00

..and so on..

Command in console 2:

cat /tmp/adc.fifo

Response in console 2 (IN1 is 1.1 volts, IN2 is zero):

1.104,0.002

1.105,0.002

1.105,0.002

1.105,0.000

..and so on..

Displaying streaming data

It’d be nice to view the streaming data in a continually-updated graph, similar to an oscilloscope display, but surprisingly few graphing utilities can handle a continuous flow of data – or they can only handle it at a very low rate.

Here are a few graphing utilities I’ve tried; they perform reasonably well on fast hardware, but struggle to maintain a good-quality graph on slower boards such as the Pi Zero – there is no problem with the data acquisition, it is just that the graphical display is very demanding.

Trend display

There is a Linux utility called ‘trend’, that can dynamically plot streaming data.

It has a wide range of options, and keyboard shortcuts, that I haven’t yet explored. The above graph was generated on a Pi 4 using the following command in one console:

sudo ./rpi_adc_stream -n 1 -l -r 5000 -s /tmp/adc.fifo

Then in a second console, the application is installed and run:

sudo apt install trend

cat /tmp/adc.fifo | trend -A f0f0f0 -I ff0000 -E 0 -s -v - 1200 600

This application is quite demanding on CPU resources, so if you are using a Pi 3, you’ll probably need to drop the sample rate to 2000.

Termeter display

Termeter is a really useful text-based dynamic display utility, written in the Go language.

You may wonder why I’m using a text-based console application to produce a graph, but it has two key advantages; it is very fast, and works on any Pi console. So if you are running the Pi ‘headless’ (i.e. remotely, with no local display) and you want to look your streaming data, you can run termeter on a remote console (e.g. ‘putty’ on windows) without the complexity of setting up an X display server.

It is installed using:

cd ~

sudo apt install golang

go get github.com/atsaki/termeter/cmd/termeter

The above data (1 sample per block, 5000 samples per second) was generated on a Pi 4 by running in one console:

sudo ./rpi_adc_stream -n 1 -r 5000 -s /tmp/adc.fifo

Then the display is started in a second console:

cat /tmp/adc.fifo | ~/go/bin/termeter

On a Pi 3, you might have to drop the sample rate to 2000, and even further on a Pi Zero.

Plotting in Python

Here is a very simple example that uses NumPy and Matplotlib to create a dynamically-updated graph of ADC data (a 10 Hz sine wave, at 200 samples per second, on a Pi 4). In one terminal, the data is generated by running:

sudo ./rpi_adc_stream -n 100 -r 200 -l -s /tmp/adc.fifo

Then run the following program in a second terminal (assuming you’ve installed Matplotlib and NumPy):

import numpy as np

from matplotlib import pyplot, animation

fifo_name = "/tmp/adc.fifo"

npoints = 100

interval = 500

xlim = (0, 1)

ylim = (0, 3.5)

fifo = open(fifo_name, "r")

fig = pyplot.figure()

ax = pyplot.axes(xlim=xlim, ylim=ylim)

line, = ax.plot([], [], lw=1)

def init():

line.set_data([], [])

return line,

def animate(i):

x = np.linspace(0, 1, npoints)

y = np.fromstring(fifo.readline(), sep=',')

line.set_data(x, y)

return line,

anim = animation.FuncAnimation(fig, animate, init_func=init,

frames=npoints, interval=interval, blit=True)

pyplot.show()

The ‘readline’ function fetches a single line of comma-delimited data, which ‘fromstring’ converts to a NumPy array.

The ‘animate’ function is used to continuously refresh the graph, however this approach is only suitable for low update rates; the time taken to do the plot is quite significant, and there is an inherent conflict between the data rate set by the streamer, and the display rate set by the animation, causing the display to stall, especially on a single-core Pi Zero. A multi-threaded program is needed to coordinate the display updates with the incoming data.

Update

The display problem has been solved by creating a fast oscilloscope-type viewer for the streaming data, using OpenGL.

Full details and source code are here, and there is a WebGL version that works remotely in a browser here.

Copyright (c) Jeremy P Bentham 2020. Please credit this blog if you use the information or software in it.

Your series on the use of DMA is a wonderful and unique work, it is very difficult to find operative guidelines to DMA programming.

After reading all your posts, I did not see any example of ADC data transfer based on end-of-conversion IRQ. Now, this is just an example, but I wonder if it’s just a chance that you did not use this technique or it’s more in general because there’s no possibility of DMA triggering via GPIO interrupt.

For my application I need an extremely low-latency and repeatable handling of the IRQ to simply write a register value, for instance starting the PWM. I have already designed a device driver that handles the hardware interrupt and I’m able to reach a latency of 4us. Unfortunately, CPU stress will make this delay randomly varying between 4 us and 16 us and DMA would definitely come in handy.

I would really appreciate if you can give me any hint in this regard.

LikeLike

The simple answer is that there is no easy way to trigger DMA on an ADC end-of-conversion.

However, you can generally work around that limitation by extending the PWM DMA control block to perform the additional tasks after a time-delay; the delay is set to a value slightly more than the maximum conversion time, as given in the ADC datasheet.

That raises the question of how to insert a time-delay into a sequence of control blocks; you can do this by adding a time-wasting dummy block transfer, with the WAITS field (TI register 25:21) set to the maximum value (31) to minimise the impact on the memory throughput.

Another workaround is to try and use an SMI data request (or even a UART input) as a hardware DMA request line, but this will be quite complicated, and I haven’t tested that it actually works.

LikeLiked by 1 person

The first thing I must say is that your series about DMA is a wonderful work. It helps me a lot.

And after reading your posts, I attempt to develop a data acquisition system. But I stuck in a problem. The ADC chip I used will generate a DRDY(Data Ready) signal repeatedly. My target is to control raspberry pi to detecting the falling edge of the DRDY signal and then trigger the DMA to activate SPI to acquire the signal. As I know, GPIO can automatically detect the falling edge and the result will record in event detect status registers. But it bothers me a lot that I can not find a way to trigger DMA by a falling edge on a GPIO pin.

I would appreciate it if you can give me any advice.

LikeLike

I agree the lack of a DMA request line is frustrating; if you can’t use fixed timing (as mentioned in my previous comment response) then you have to look at the peripherals with a DMA interface, and see which one can be used to simulate a DMA request. I’d start by taking a look at SMI data read/write requests, but the coding isn’t going to be easy; hopefully I’ll get around to doing some tests of this method soon.

LikeLike

Well, that would be great to configure a line to be used as DMA request. As a curiosity, do you have an idea of the time required to start a DMA task from the moment in which you issue the command start_dma(… to the moment in which the memory transfer actually happen?

LikeLike

If you are lucky, a few microseconds. If unlucky (i.e. another interrupt occurs while the command is being executed) then a few hundred. It all depends on what else the CPUs are doing, and therein lies the problem…

LikeLike

Hi,

I just wanted to say that this was really a good article. I was trying to acquire data from an IMU at 25.6kHz and this solved my problem. I had some issues with it. But nothing that couldn’t be solved. Thank you a lot. And since you helped me, I will try to help you with the plotting. There is a library in python that can do realtime plotting. It is called pyqtgraph, maybe it can help you. Once again thanks a lot. 🙂

LikeLike

Very great and useful article! Thank you

I have a case that a batch of data receives every 20 milliseconds. Besides, I have to set the sample rate almost high around 100000. For this, I use the single-mode and start and stop streaming repeatedly every 20 milliseconds. Normally, there is no problem and the data acquisition works fine. However, in some cases, for example, when there is some video manipulation (such as stopping or starting a video), the beginnings of some batches are lost. It seems that the TX CB acts without problem because the microcontroller attached responses to the TX, but the RX CB fails. In other words, the data sent by the slave are not saved to RX buffers. I have set the SPI clock to 4 MegaHertz and the sample rate to 100000.

Is there any way that I can solve this problem?

Thanks in advance.

LikeLike

Changing the DMA priority might fix this, but it is possible you are briefly exceeding the memory bandwidth, in which case tinkering with the DMA won’t fix the problem; in that case, maybe add a variable delay to the video operation, so it always occurs mid-way between 2 data samples.

LikeLike

Hi,

can only agree with others here – great work.

I tried it running on RPi3 and it did work out-of-the-box.

Also on a RPi4 – but here I tried as well to transfer it quick and dirty simply to use the new SPI6.

But I did run in some problems – getting segmentation fault – ok, I need to dig into that a bit more.

Anybody here having tried it as well – maybe with success and can provide a hint?

LikeLike

What about if we use SPI1 instead of SPI0 peripheral. Should we change SPIO_BASE address? I changed SPI_CS, SPI_MISO, SPI_MISO, SPI_CLOCK pins and alternates but it doesn’t work.

LikeLike

Yes, but to be honest I haven’t tested the code with SPI1

LikeLike

Hi, thanks you for your great article, great work.

I’m trying to work with Raspberry Pi & MCP3201 and I can’t get it to work.

Do you know what changes i should make to make it work?

Best regards

LikeLike

Afraid I have no experience with this device, and don’t have the time to work something out. Probably the closest device I’ve used is the ADS7884, as in my post https://iosoft.blog/fast-data-capture-raspberry-pi/

Unfortunately I have too many calls on my time to offer any help with individual projects.

LikeLike

Hi, this is a really good example of using SPI with PWM and DMA! I wonder how fast the PWM can be. I have a project that needs the sample rate to be 640KS/s, which means the PWM and SPI_CS must run at this number. Do you think it’s possible? How do I match the rates for PWM, SPI_CS and SPI_CLK?

LikeLike

The SPI clock must just be fast enough to allow the sample to be acquired, with a bit of extra time for asserting and negating the chip select. Unfortunately I can’t get into specifics, since I already have too many projects and too little time, but you can see various examples in my other posts, e.g. https://iosoft.blog/fast-data-capture-raspberry-pi/

LikeLike

Hello and thank you for this tremendous work! I found useful tool ‘Trend’ here (great). Anyway, its manual is rather skinny. Do you know how to remove ‘history’ from display? (with -s option for scrolling only 1st screen width is without history, later it comes in, thus making plot littered)

LikeLike

No, sadly I haven’t worked out how to fix this, so don’t use Trend any more.

LikeLike

Why do I get a PWM bus error when I type ‘sudo ./rpi_adc_stream -t’?

LikeLike

I haven’t encountered that error, but assume that you have some other software running that is using the same PWM.

LikeLike

Great article. I am using mcp3008 on a pi zero w. I can print the data to stdout, but when I pipe it to termeter it errors and then tells me broken pipe

-bash: /home/pi/go/bin/termeter: No such file or directory

I tried just running termeter and I get command not found. The only folder in the go folder is src. Is there perhaps a missing step in your install instructions? The git repository for termeter was no help in this.

Thanks!

LikeLike

It looks like they’ve changed the installation, see https://github.com/atsaki/termeter/issues/7

LikeLike