It has been a long haul, but we are now getting close to doing something useful with the WiFi chip; we just need to tackle the issue of IOCTLs.

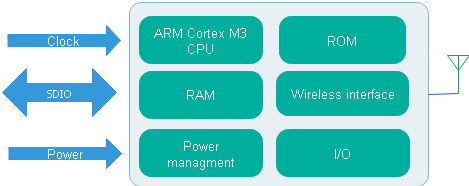

You may already be familiar with these from configuring a serial link, or network hardware; they provide a programming interface into a vendor-specific driver. Since the BCM/CTW43xxx chips are intelligent (they have their own CPU) the IOCTL calls are handled directly by the firmware we’ve programmed into the chip. So even though we’re in ‘bare metal’ mode, without an operating system, we still need to handle IOCTLs.

The IOCTL calls are listed in the wwd_wlioctl.h in WICED or WiFi Host Driver, or wlioctl_defs.h, and there are over 300 of them; this post will concentrate on the code that sends IOCTL requests and handles the responses, and we’ll check they are working by doing a quick network scan – more interesting things, like transmission & reception, will have to wait for the next part.

Message structure

When using IOCTL calls, you are essentially writing a data packet to the WiFi RAM, waiting for an acknowledgement, then reading back the response. As you’d expect, there is a specific data format for the requests and responses, though it does have some strange features:

#define IOCTL_MAX_DLEN 256

typedef struct {

uint8_t seq, // sdpcm_sw_header

chan,

nextlen,

hdrlen,

flow,

credit,

reserved[2];

uint32_t cmd; // CDC header

uint16_t outlen,

inlen;

uint32_t flags,

status;

uint8_t data[IOCTL_MAX_DLEN];

} IOCTL_CMD;

typedef struct {

uint16_t len;

uint8_t reserved1,

flags,

reserved2[2],

pad[2];

} IOCTL_GLOM_HDR;

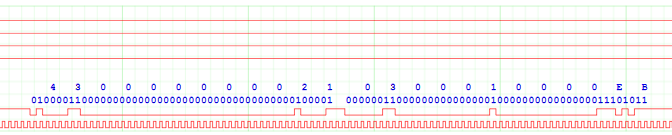

The best feature of the IOCTL data is that it always starts with a 16-bit length word, followed by the bitwise inverse of that length (least-significant byte first). For example, here is the decode of a request to set a variable ‘bus:rxglom’ to a value of 1:

19.290643 * Cmd 53 A500002C Wr WLAN 08000 len 44

19.290669 * Rsp 53 00001000 Flags 10

Data 44 bytes: 2b 00 d4 ff 00 00 00 0c 00 00 00 00 07 01 00 00 0f 00 00 00 02 00 02 00 00 00 00 00 62 75 73 3a 72 78 67 6c 6f 6d 00 01 00 00 00 00 *

IOC_W 44 bytes: seq=0 chan=0 nextlen=0 hdrlen=C flow=0 credit=0 cmd=107 outlen=F inlen=0 flags=20002 status=0 set 'bus:rxglom'

19.290769 Ack 2F FF

You can check this is an IOCTL message by adding the first two bytes to the second two: 002B + FFD4 = FFFF. It uses a command 53 to send a 44-byte request (actually 43 bytes, rounded up to nearest 4-byte value) to the RAD function, containing a header of mostly zeros with an IOCTL number of 107 hex (263 decimal) to set a variable, a null-terminated variable name, then the binary value.

It is then necessary to poll the WiFi chip to check when the response is available, and if so, acknowledge it:

19.291055 * Cmd 53 15404004 Rd BAK 180000:A020 len 4

Data 4 bytes: 40 00 80 00 *

19.291081 * Rsp 53 00001000 Flags 10

19.291179 * Cmd 53 95404004 Wr BAK 180000:A020 len 4

19.291205 * Rsp 53 00001000 Flags 10

Data 4 bytes: 40 00 00 00 *

19.291259 Ack 28 3F

The value of 40 hex in backplane register 2020 (A020 for a 32-bit value) shows there is a response, which is acknowledged by writing 40 hex to that register, then the response is read:

19.291377 * Cmd 53 21000040 Rd WLAN 08000 len 64

19.291403 * Rsp 53 00001000 Flags 10

Data 64 bytes: 2b 00 d4 ff 02 00 00 0c 00 11 00 00 07 01 00 00 0f 00 00 00 00 00 02 00 00 00 00 00 62 75 73 3a 72 78 67 6c 6f 6d 00 01 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 *

IOC_R 64 bytes: seq=2 chan=0 nextlen=0 hdrlen=C flow=0 credit=11 cmd=107 outlen=F inlen=0 flags=20000 status=0 set 'bus:rxglom'

The response is the same length as the request, and when writing to a variable it is largely a copy of the command. When receiving the response, it is important to check that it matches the request, as the two can easily get out of step. Unfortunately the sequence number can’t be used for this purpose (in this example the response is 2, and request is 0) instead the most-significant 16 bits of the ‘flags’ are a ‘request ID’ that should be the same for request & response, while the lower 16 bits are set to 2 for a write cycle, 0 for a read.

Equally strange is that the command length always seems to be the same as the response, so for a short command with a long response (such as ‘ver’) the command is 296 bytes long, just to carry a 3-character name. This is a bit crazy; sometime I’ll experiment with the header fields to see if there is a way round it.

Glom

I’ll admit this word wasn’t in my vocabulary until I encountered it in the WiFi drivers, and I’m still not entirely clear what it means. The transaction above sets ‘rxglom’ to 1, which enables ‘glom’ mode for incoming commands (‘rx’ refers to the WiFi chip command reception, not the host).

After this is set, another header is introduced into commands sent to the WiFi chip; I have accommodated this using another structure, and a union to cover both.

typedef struct {

uint16_t len;

uint8_t reserved1,

flags,

reserved2[2],

pad[2];

} IOCTL_GLOM_HDR;

typedef struct {

IOCTL_GLOM_HDR glom_hdr;

IOCTL_CMD cmd;

} IOCTL_GLOM_CMD;

typedef struct

{

uint16_t len, // sdpcm_header.frametag

notlen;

union

{

IOCTL_CMD cmd;

IOCTL_GLOM_CMD glom_cmd;

};

} IOCTL_MSG;

The good news is that the first 4 bytes of any message remain the same (16-bit length, and its bitwise inverse); the bad news is that the new header is shoehorned in after that, pushing the other headers out by 8 bytes.

Here is an example: getting ‘cur_ethaddr’ which is the 6-byte MAC address:

19.291837 * Cmd 53 A5000038 Wr WLAN 08000 len 56

19.291863 * Rsp 53 00001000 Flags 10

Data 56 bytes: 38 00 c7 ff 34 00 00 01 00 00 00 00 01 00 00 14 00 00 00 00 06 01 00 00 14 00 00 00 00 00 03 00 00 00 00 00 63 75 72 5f 65 74 68 65 72 61 64 64 72 00 00 00 00 00 00 00 *

IOC_W 56 bytes: seq=1 chan=0 nextlen=0 hdrlen=14 flow=0 credit=0 cmd=106 outlen=14 inlen=0 flags=30000 status=0 get 'cur_etheraddr'

19.291973 Ack 2F FF

I’m sure there must be some point to the extended header, but right now I’m not at all sure what it is. There doesn’t seem to be any official marker in the glom header to show that it has been included, which makes life difficult for any software attempting to decode the IOCTLs. For the time being, I’m hedging my bets by using a global variable to enable or disable this option, and leaving it disabled; hopefully its true purpose will be clear soon.

Partial data read

If the IOCTL command has a long response, and the software doesn’t read it all, the remainder will still be available for the next read. This can be demonstrated by the version (‘ver’) command; even though it is sent as a single 296-byte block, the Linux driver receives it as one block of 64 bytes, then another of 224:

19.295186 * Cmd 53 A5000128 Wr WLAN 08000 len 296

19.295212 * Rsp 53 00001000 Flags 10

Data 296 bytes: 28 01 d7 fe 24 01 00 01 00 00 00 00 03 00 00 14 00 00 00 00 06 01 00 00 04 01 00 00 00 00 05 00 00 00 00 00 76 65 72 00 76 65 72 00 00 ..and so on..

IOC_W 296 bytes: seq=3 chan=0 nextlen=0 hdrlen=14 flow=0 credit=0 cmd=106 outlen=104 inlen=0 flags=50000 status=0 get 'ver'

19.295583 Ack 2F FF

19.295980 * Cmd 52 00000A00 Rd BUS 00005

19.296006 * Rsp 52 00001002 Flags 10 data 02

19.296178 * Cmd 53 15404004 Rd BAK 180000:A020 len 4

Data 4 bytes: 40 00 80 00 *

19.296204 * Rsp 53 00001000 Flags 10

19.296321 * Cmd 53 95404004 Wr BAK 180000:A020 len 4

19.296347 * Rsp 53 00001000 Flags 10

Data 4 bytes: 40 00 00 00 *

19.296404 Ack 28 3F

19.296563 * Cmd 53 21000040 Rd WLAN 08000 len 64

19.296589 * Rsp 53 00001000 Flags 10

Data 64 bytes: 20 01 df fe 05 00 00 0c 00 14 00 00 06 01 00 00 04 01 00 00 00 00 05 00 00 00 00 00 77 6c 30 3a 20 4f 63 74 20 32 33 20 32 30 31 37 20 30 33 3a 35 35 3a 35 33 20 76 65 72 73 69 6f 6e 20 37 2e *

IOC_R 64 bytes: seq=5 chan=0 nextlen=0 hdrlen=C flow=0 credit=14 cmd=106 outlen=104 inlen=0 flags=50000 status=0 get 'wl0: Oct 23 2017 03:55:53 version 7.'

19.296841 * Cmd 53 210000E0 Rd WLAN 08000 len 224

19.296867 * Rsp 53 00001000 Flags 10

Data 224 bytes: 34 35 2e 39 38 2e 33 38 20 28 72 36 37 34 34 34 32 20 43 59 29 20 46 57 49 44 20 30 31 2d 65 35 38 64 32 31 39 66 0a 00 00 ..and so on..

This serves to emphasise the important of reading all the data from every response, and checking that the Request ID matches that of the response; it’d be all to easy for the network driver to lose track.

Events

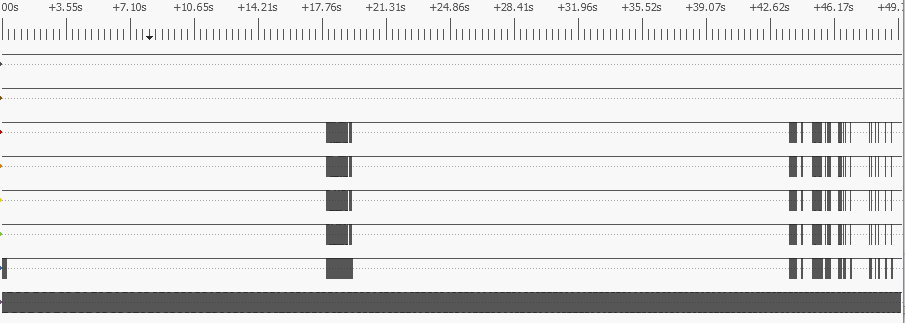

So far, we’ve dealt had a strict one-to-one matching between request and response, but how does the WiFi chip indicate when it has extra data available? For example, a single network scan may generate 10 or 20 data blocks (one for every access point), how does the host know when this data is available? There is mention of an interrupt pin (which we’ll save for a future blog) but how can the driver software check for data pending?

I puzzled over this for some time, on the assumption there must be a special register to indicate this, but in the end it seems that the driver just issues a normal data read; if data is available it can be recognised by the length header, if not zeros are returned.

The WiFi chip has a finite amount of buffer space to queue up such events; this is the ‘credit’ value in the IOCTL header; presumably the network driver should check this to see if events have been lost due to running out of buffers.

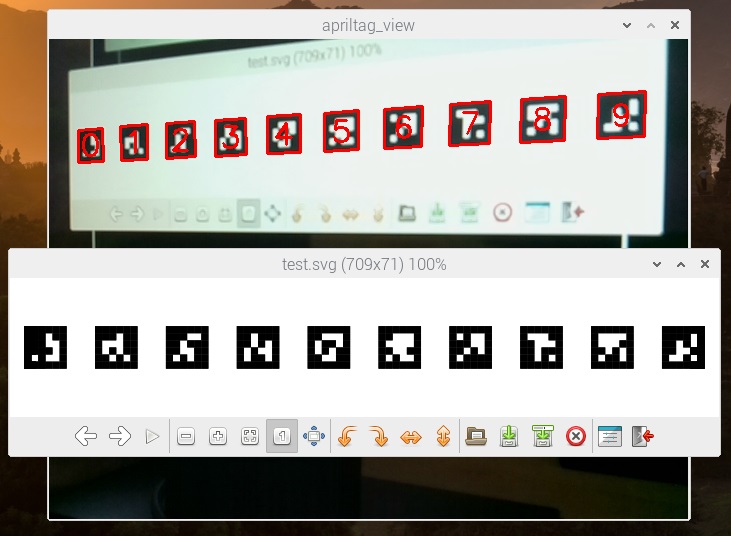

Network scan

Finally, we get to do something vaguely useful; scan for WiFi networks. There are 2 types: ‘iscan’ and ‘escan’. The first is an incremental scan, that seems easier to use, but is marked as ‘deprecated’ in some source code. The second is supposed to be more versatile (i.e. more complicated) but is the preferred option, so that is what we’ll be using.

We need to fill in a structure with the scan parameters; due to the large number of networks in the vicinity, I usually scan a single channel:

// WiFi channel number to scan (0 for all channels)

#define SCAN_CHAN 1

typedef struct {

uint32_t version;

uint16_t action,

sync_id;

uint32_t ssidlen;

uint8_t ssid[32],

bssid[6],

bss_type,

scan_type;

uint32_t nprobes,

active_time,

passive_time,

home_time;

uint16_t nchans,

nssids;

uint8_t chans[14][2],

ssids[1][32];

} SCAN_PARAMS;

SCAN_PARAMS scan_params = {

.version=1, .action=1, .sync_id=0x1234, .ssidlen=0, .ssid={0},

.bssid={0xff,0xff,0xff,0xff,0xff,0xff}, .bss_type=2, .scan_type=1,

.nprobes=~0, .active_time=~0, .passive_time=~0, .home_time=~0,

#if SCAN_CHAN == 0

.nchans=14, .nssids=0,

.chans={{1,0x2b},{2,0x2b},{3,0x2b},{4,0x2b},{5,0x2b},{6,0x2b},{7,0x2b},

{8,0x2b},{9,0x2b},{10,0x2b},{11,0x2b},{12,0x2b},{13,0x2b},{14,0x2b}},

#else

.nchans=1, .nssids=0, .chans={{SCAN_CHAN,0x2b}}, .ssids={{0}}

#endif

};

The scan is triggered by sending this data in an ‘escan’ IOCTL call, but first we must tell the chip that we’re interested in the response events. This is done by sending a very large bitfield, with a bit set for each event you want to receive; there are over 140 possible events, so you need to pick the right one. I got the list from whd_events_int.h which is part of the Cypress WiFi Host Driver project; if you don’t know what that is, please refer to part 1 of this blog, which describes all the resources I’m using.

So the code to trigger the scan becomes:

#define EVENT_ESCAN_RESULT 69

#define EVENT_MAX 160

#define SET_EVENT(e) event_msgs[e/8] = 1 << (e & 7)

uint8_t event_msgs[EVENT_MAX / 8];

SET_EVENT(EVENT_ESCAN_RESULT);

ioctl_set_data("event_msgs", event_msgs, sizeof(event_msgs));

ioctl_set_data("escan", &scan_params, sizeof(scan_params));

Surprisingly easy, until we get back the results of the scan, which has one varying-length record for every WiFi access point found. There is a lot of data, around 300 to 600 bytes per record, so we need to do some heavyweight decoding.

Decoding the scan data

So far, I’ve avoided including any of the standard Cypress / Broadcom header files in my project. This is because any one header file often depends on another 2, which then depends on another 5, and so on… Quite rapidly, you’re including a large chunk of the Operating System which isn’t at all necessary; it just makes the decoding process much harder to follow.

Fortunately for this project, there is a way to avoid these major OS dependencies; use header files that were created for use in embedded systems, namely the Cypress WiFi Host Driver described in part 1 of this blog. Here are the structures that are needed for decoding the scan response data, and the files they’re in:

whd_types.h:

whd_security, whd_scan_type, whd_bss_type, whd_802_11_band, whd_mac, whd_ssid, whd_bss_type,

whd_event_header [-> whd_event_msg], wl_bss_info

whd_events.h:

whd_event_ether_header, whd_event_eth_hdr, whd_event_msg, whd_event

whd_wlioctl.h:

wl_escan_result

Additional dependencies for these files are in:

cy_result.h, cyhal_hw_types.h, whd.h

So only 6 extra files need to be included at this stage, and we’ve avoided the unnecessary complexity of an Operating System interface – after all, this driver is supposed to be bare-metal code.

The code to print the MAC address, channel number and SSID (network name) is:

// Escan result event (excluding 12-byte IOCTL header)

typedef struct {

uint8_t pad[10];

whd_event_t event;

wl_escan_result_t escan;

} escan_result;

escan_result *erp = (escan_result *)eventbuff;

n = ioctl_get_event(eventbuff, sizeof(eventbuff));

if (n > sizeof(escan_result))

{

printf("%u bytes\n", n);

disp_mac_addr((uint8_t *)&erp->event.whd_event.addr);

printf(" %2u ", SWAP16(erp->escan.bss_info->chanspec));

disp_ssid(&erp->escan.bss_info->SSID_len);

}

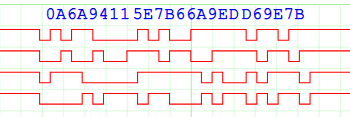

The scan result data fields are in network-standard byte-order (big endian) so the channel number needs to be byte-swapped.

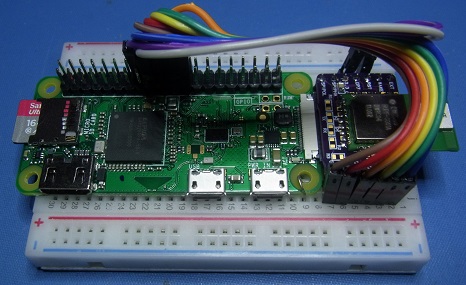

Running the code

If you want to try out the code so far, you’ll need a Pi ZeroW with a USB-serial cable attached, the arm-none-eabi-gcc compiler and gdb debugger. You can find full details and a simple test program here; it is worth running this before attempting the Zerowi project.

The source code is at https://github.com/jbentham/zerowi, ‘make_scan.bat’ will create zerowi.elf on windows, which is downloaded into the target using the ‘run’ batch file. This executes alpha_speedup.py to accelerate the serial link from 115200 to 921600 baud, then runs Arm gdb using the setup commands in run.gdb.

I have provided Linux scripts ‘make_scan’ and ‘run’, these need to be made executable using ‘chmod +x’. The Alpha debugger does require arm-none-eabi-gdb, which isn’t included in many Linux distributions (including Raspbian Buster) so may need to be built from source.

My Windows system uses serial port COM7, and Linux uses /dev/ttyUSB0; yours may well be different, so you’ll need to change scripts accordingly. If the Cypress firmware is included in the build image (i.e. ‘INCLUDE_FIRMWARE’ is non-zero) then it will take around 10 seconds to load the executable image onto the ZeroW. When the code runs you should see a list of access points; to keep the number of entries low, I only scan a single channel, by default channel 1:

360 bytes

7A:30:D9:96:DA:xx 1 BTWifi-X

460 bytes

84:A4:23:04:81:xx 1 PLUSNET

360 bytes

BC:30:D9:96:DA:xx 1 BTHub6

456 bytes

20:E5:2A:0E:A1:xx 1 Virginia Drive

312 bytes

7A:30:D9:96:DA:xx 1 BTWifi-with-FON

312 bytes

00:1D:AA:C1:75:xx 1 testnet

The last of the these is a special test network I’ll be using in subsequent parts of this blog.

To select another channel, change SCAN_CHAN at the top of zerowi.c; if set to zero, all channels will be scanned.

[Overview] [Previous part] [Next part]

Copyright (c) Jeremy P Bentham 2020. Please credit this blog if you use the information or software in it.