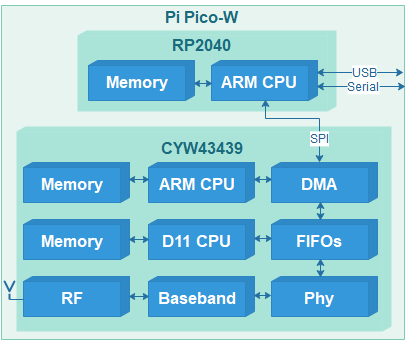

In part 1, I described the low-level hardware & software interface to the Broadcom / Cypress / Infineon CYW43439 WiFi chip, and its close relative, the CYW4343W.

Now we need to initialise the chip, so it is ready to receive network commands and data. This involves sending three files to the chip, and unfortunately there is no simple Application Programming Interface (API) to do this; it is necessary to send a detailed sequence of commands, and if there are any errors, you usually end up with a completely unresponsive WiFi chip.

The first step is to check the Active Low Power (ALP) clock; this involves setting a register, then waiting for the WiFi chip to acknowledge that setting.

bool wifi_init(void)

{

wifi_reg_write(SD_FUNC_BAK, BAK_CHIP_CLOCK_CSR_REG, SD_ALP_REQ, 1);

if (!wifi_reg_val_wait(10, SD_FUNC_BAK, BAK_CHIP_CLOCK_CSR_REG,

SD_ALP_AVAIL, SD_ALP_AVAIL, 1))

return(false);

This wait-and-loop scenario is quite common, so I’ve created a specific function for it:

// Check register value every msec, until correct or timeout

bool wifi_reg_val_wait(int ms, int func, int addr, uint32_t mask, uint32_t val, int nbytes)

{

bool ok;

while (!(ok=wifi_reg_read_check(func, addr, mask, val, nbytes)) && ms--)

usdelay(1000);

return(ok);

}

// Read & check a masked value, return zero if incorrect

bool wifi_reg_read_check(int func, int addr, uint32_t mask, uint32_t val, int nbytes)

{

return((wifi_reg_read(func, addr, nbytes) & mask) == val);

}

A value is obtained from the register, masked with an AND-function, then compared with the required value. If the comparison is false, the code delays for one millisecond, then tries again, until the given time (in milliseconds) has expired.

This raises the question as to what the code should do when it encounters an error such as this; should it try to re-send the command? In practice, the timeout generally means that the internal state of the chip is incorrect; for example, there may have been a bug in the code, or a power glitch, and the only way to correct this situation is to re-power the chip, and start again – fortunately the initialisation process is quite fast (it only takes a few seconds) so this isn’t a major problem.

Assuming the ALP check passes, there are some more register write cycles that I can’t explain in detail, as I don’t have access to any information about the chip that isn’t publicly available.

We then make 2 writes to registers in banked memory, that do deserve more explanation.

#define BAK_BASE_ADDR 0x18000000

#define SRAM_BASE_ADDR (BAK_BASE_ADDR+0x4000)

#define SRAM_BANKX_IDX_REG (SRAM_BASE_ADDR+0x10)

#define SRAM_BANKX_PDA_REG (SRAM_BASE_ADDR+0x44)

wifi_bak_reg_write(SRAM_BANKX_IDX_REG, 0x03, 4);

wifi_bak_reg_write(SRAM_BANKX_PDA_REG, 0x00, 4);

The backplane function can only access a 32K block in the WiFi RAM, so the two addresses we’re writing (18004010 and 18004044 hex) are outside its access range, and we have to use bank-switching. There is a simple check to see if the bank has changed since the last access, in which case no switching is needed:

#define SB_32BIT_WIN 0x8000

#define SB_ADDR_MASK 0x7fff

#define SB_WIN_MASK (~SB_ADDR_MASK)

// Set backplane window if address has changed

void wifi_bak_window(uint32_t addr)

{

static uint32_t lastaddr=0;

addr &= SB_WIN_MASK;

if (addr != lastaddr)

wifi_reg_write(SD_FUNC_BAK, BAK_WIN_ADDR_REG, addr>>8, 3);

lastaddr = addr;

}

// Write a 1 - 4 byte value via the backplane window

int wifi_bak_reg_write(uint32_t addr, uint32_t val, int nbytes)

{

wifi_bak_window(addr);

return(wifi_reg_write(SD_FUNC_BAK, addr, val, nbytes));

}

We can now load the binary ARM firmware into the WiFi processor; it is in a file that is unique to the specific Wifi chip, so different files are needed for the CYW43439 and CYW4343w; these are the only differences in the way the chips are programmed.

const unsigned char fw_firmware_data[] = {

0x00,0x00,0x00,0x00,0x65,0x14,0x00,0x00,0x91,0x13,0x00,0x00,0x91,0x13,0x00,0x00,0x91,0x13,0x00,0x00,0x91,0x13,0x00,0x00,0x91,0x13,0x00,0x00,0x91,0x13,0x00,0x00,0x91,0x13,0x00,0x00,0x91,0x13,0x00,0x00,

..and so on..

}

const unsigned int fw_firmware_len = sizeof(fw_firmware_data);

wifi_data_load(SD_FUNC_BAK, 0, fw_firmware_data, fw_firmware_len);

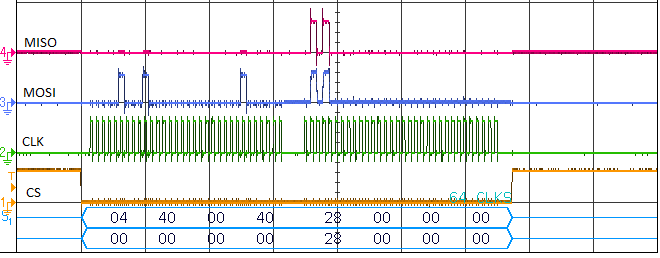

As previously mentioned, the backplane can only access a 32K block, and each SPI access to the backplane is limited to 64 bytes, so the data loading function walks though the memory in 64-byte blocks, and when 32K is reached, the access window is moved up, and the loading resumes at address 0.

#define MAX_BLOCKLEN 64

// Load data block into WiFi chip (CPU firmware or NVRAM file)

int wifi_data_load(int func, uint32_t dest, const unsigned char *data, int len)

{

int nbytes=0, n;

uint32_t oset=0;

wifi_bak_window(dest);

dest &= SB_ADDR_MASK;

while (nbytes < len)

{

if (oset >= SB_32BIT_WIN)

{

wifi_bak_window(dest+nbytes);

oset -= SB_32BIT_WIN;

}

n = MIN(MAX_BLOCKLEN, len-nbytes);

wifi_data_write(func, dest+oset, (uint8_t *)&data[nbytes], n);

nbytes += n;

oset += n;

}

return(nbytes);

}

After a delay to allow the WiFi chip to settle, the next item to be loaded is the non-volatile RAM (NVRAM) data. This is in the form of a C character array, with each entry being null-terminated, e.g.

const unsigned char fw_nvram_data[0x300] = {

"manfid=0x2d0" "\x00"

"prodid=0x0727" "\x00"

"vendid=0x14e4" "\x00"

..and so on..

}

const unsigned int fw_nvram_len = sizeof(fw_nvram_data);

Loading this file uses the same function as the firmware, with a different base, and a write-cycle to confirm the file length:

#define NVRAM_BASE_ADDR 0x7FCFC

wifi_data_load(SD_FUNC_BAK, NVRAM_BASE_ADDR, fw_nvram_data, fw_nvram_len);

n = ((~(fw_nvram_len / 4) & 0xffff) << 16) | (fw_nvram_len / 4);

wifi_reg_write(SD_FUNC_BAK, SB_32BIT_WIN | (SB_32BIT_WIN-4), n, 4);

Now it is necessary to reset the WiFi processor core, wait for the indication that the High Throughput (HT) clock is available, then wait for an ‘event’ that signals the device is ready. The most common fault I experienced when developing the code was that it gets stuck at this point, waiting for a confirmation that never comes.

// Reset, and wait for High Throughput (HT) clock ready

wifi_core_reset(false);

if (!wifi_reg_val_wait(50, SD_FUNC_BAK, BAK_CHIP_CLOCK_CSR_REG,

SD_HT_AVAIL, SD_HT_AVAIL, 1))

return(false);

// Wait for backplane ready

if (!wifi_rx_event_wait(100, SPI_STATUS_F2_RX_READY))

return(false);

Events are the main way that the WiFi chip sends signals or data asynchronously to the RP2040; for a detailed description of how they work, see the next part.

Once the system has signalled it is ready, the Country Locale Matrix (CLM) file has to be loaded. This binary file limits the WiFi parameters (e.g. transmit power level) to be within the regulatory constraints for the specific RF hardware and locale.

const unsigned char fw_clm_data[] = {

0x42,0x4C,0x4F,0x42,0x3C,0x00,0x00,0x00,0xFA,0x69,0xE0,0xBB,

0x01,0x00,0x00,0x00,0x02,0x00,0x00,0x00,0x00,0x00,0x00,0x00,

..and so on..

};

const unsigned int fw_clm_len = sizeof(fw_clm_data);

wifi_clm_load(fw_clm_data, fw_clm_len);

The loading function uses a specific structure to send IOCTL data blocks to the WiFi chip, with flags to mark the beginning & end of the sequence:

#define MAX_LOAD_LEN 512

typedef struct {

uint16_t flag;

uint16_t type;

uint32_t len;

uint32_t crc;

} CLM_LOAD_HDR;

typedef struct {

char req[8];

CLM_LOAD_HDR hdr;

} CLM_LOAD_REQ;

// Load CLM

int wifi_clm_load(const unsigned char *data, int len)

{

int nbytes=0, oset=0, n;

CLM_LOAD_REQ clr = {.req="clmload", .hdr={.type=2, .crc=0}};

while (nbytes < len)

{

n = MIN(MAX_LOAD_LEN, len-nbytes);

clr.hdr.flag = 1<<12 | (nbytes?0:2) | (nbytes+n>=len?4:0);

clr.hdr.len = n;

ioctl_set_data2((void *)&clr, sizeof(clr), 1000, (void *)&data[oset], n);

nbytes += n;

oset += n;

}

return(nbytes);

}

Example program

To show all this code in action, we can run our first complete program;

// PicoWi blinking LED test

#include <stdint.h>

#include <stdbool.h>

#include <stdio.h>

#include "picowi_pico.h"

#include "picowi_spi.h"

#include "picowi_init.h"

int main()

{

uint32_t led_ticks;

bool ledon=false;

io_init();

printf("PicoWi LED blink\n");

set_display_mode(DISP_INFO);

if (!wifi_setup())

printf("Error: SPI communication\n");

else if (!wifi_init())

printf("Error: can't initialise WiFi\n");

else

{

ustimeout(&led_ticks, 0);

while (1)

{

if (ustimeout(&led_ticks, 500000))

wifi_set_led(ledon = !ledon);

}

}

}

This sets up the WiFi chip as described above, prints the 6-byte MAC address, then just loops, flashing the LED that is attached to the Wifi chip at 1 Hz.

The display_mode function controls how much diagnostic information you might want to see, using a bitfield so you can combine multiple options:

// Display mask values

#define DISP_NOTHING 0 // No display

#define DISP_INFO 0x01 // General information

#define DISP_SPI 0x02 // SPI transfers

#define DISP_REG 0x04 // Register read/write

#define DISP_SDPCM 0x08 // SDPCM transfers

#define DISP_IOCTL 0x10 // IOCTL read/write

#define DISP_EVENT 0x20 // Event reception

#define DISP_DATA 0x40 // Data transfers

This can potentially provide a lot of diagnostic information, the main limitation being the speed of the console display – I use a serial link at 460800 baud, since the default of 9600 is much too slow. To see some of the internal workings of PicoWi, try:

set_display_mode(DISP_INFO|DISP_REG|DISP_IOCTL);

You can call this function multiple times with different mode values, to concentrate the diagnostic information on a specific area of interest, and avoid displaying a lot of unwanted information while the WiFi chip is being initialised.

The other unusual feature is the use of the ustimeout function, which I’ve used it in place of the more conventional delay function call, as I don’t want the delay to block all other CPU activity. In a simple program this isn’t an issue, but in later examples I want to do other things (such as checking for events) while waiting for the LED to blink, so can’t use a simple delay.

The ustimeout function takes two arguments; a pointer to a variable, and a timeout value in microseconds (zero if immediate). When the specified time has elapsed, the function returns a non-zero value and reloads the variable with the current time. So you can add extra function calls to the main loop, without affecting the LED blinking.

The code to control the LED uses a single Device I/O Control (IOCTL) call with 2 arguments; the first is a bit-mask, and the second is the value:

#define SD_LED_GPIO 0

// Set WiFi LED on or off

void wifi_set_led(bool on)

{

ioctl_set_intx2("gpioout", 10, 1<<SD_LED_GPIO, on ? 1<<SD_LED_GPIO : 0);

}

For details on how to build & run this example program, see the introduction.

IOCTL calls are the primary mechanism for high-level communication with the WiFi chip; see the next part for a detailed description.

| Project links | |

|---|---|

| Introduction | Project overview |

| Part 1 | Low-level interface; hardware & software |

| Part 2 | Initialisation; CYW43xxx chip setup |

| Part 3 | IOCTLs and events; driver communication |

| Part 4 | Scan and join a network; WPA security |

| Part 5 | ARP, IP and ICMP; IP addressing, and ping |

| Part 6 | DHCP; fetching IP configuration from server |

| Part 7 | DNS; domain name lookup |

| Part 8 | UDP server socket |

| Part 9 | TCP Web server |

| Part 10 | Web camera |

| Source code | Full C source code |

Copyright (c) Jeremy P Bentham 2022. Please credit this blog if you use the information or software in it.